» Durofit Sliding Bearings

Sliding bearing or Bushing or sleeve bearings which it generally called is an independent plain bearing that is inserted into a housing to provide a bearing surface supporting rotary or linear movement demanding applications which are normally high load but relatively low RPM especially used in absence of additional grease or oil. These bearings are made from ‘processed’ sheets or from specially formulated casting made different shapes of cylindrical (for linear & rotary motion), with a flange (thrust loading alongwith rotary movement), a thrust washer as well as in strip (mostly sliding appn) form apart from taking different forms as demanded by the application and surrounding components. There is vast range available in stand- ard form in both metric as well Inch dimension used by designers to incorporate in their designs from the proto stage.

Sliding bearing or Bushing or sleeve bearings which it generally called is an independent plain bearing that is inserted into a housing to provide a bearing surface supporting rotary or linear movement demanding applications which are normally high load but relatively low RPM especially used in absence of additional grease or oil. These bearings are made from ‘processed’ sheets or from specially formulated casting made different shapes of cylindrical (for linear & rotary motion), with a flange (thrust loading alongwith rotary movement), a thrust washer as well as in strip (mostly sliding appn) form apart from taking different forms as demanded by the application and surrounding components. There is vast range available in stand- ard form in both metric as well Inch dimension used by designers to incorporate in their designs from the proto stage.

» Duroglyd Bearings

Duroglyd bearings range denotes the range of sliding bearings durofit manufactuires whoch are 100% self lubricated by deafult and some are with pre-lubrication which hitherto are mentioned in specific. These bearings are suitable for very less coefficient friction, excellent sliding charecteristics insuring very low wear rating. The initial movment make sure that a certain level of lubricant is passed on to the shaft, where by avoiding metal to metal contact to the minimum as well as protection. This ebaring range is suitable for oscillation, rotary, high chemical resistance, low absorption of water and swelling. It is to be noted that with some extra lubrication sliding bearings performs better.

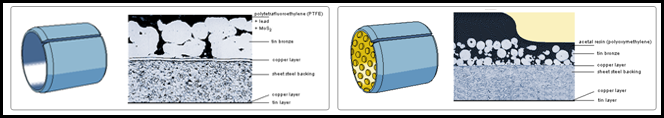

Internal Structure

The bearings made from strips or coil has s lit along the length of the bushing and those made from casting, extrusion or from forged material doesn’t. The split bearings generally take the final form depending on the housing (Bushing OD ref) as these are press fitted and relatively the final bore (Bushing ID ref) changes which in most cases are predetermined as mentioned in the catalogue.The bearing performance mostly depends on the final clearance between the shaft OD and the clearance between the final bore of the bush, bearing or the sleeve.